Ultrasonic Flow Meters

Introduction to Ultrasonic Doppler Flow Meters

An ultrasonic flow meter (non-intrusive Doppler flow meters) is a volumetric flow meter which requires particulates or bubbles in the flow. Ultrasonic flow meters are ideal for wastewater applications or any dirty liquid which is conductive or water based. Ultrasonics flow meters will generally not work with distilled water or drinking water. Aerations would be required in the clean

liquid applications. Ultrasonic flow meters are also ideal for applications where low pressure drop, chemical compatibility, and low maintenance are required.

OMEGA Engineering offers a wide range of

ultrasonic flow meters in Taiwan.

The Ultrasonic Doppler Flow Sensor

Principle of operation

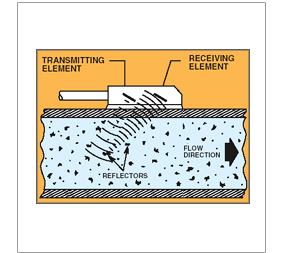

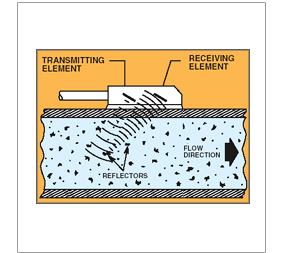

The basic principle of operation employs the frequency shift (Doppler Effect) of an ultrasonic signal when it is reflected by suspended particles or gas bubbles (discontinuities) in motion. This metering technique utilizes the physical phenomenon of a sound wave that changes frequency when it is reflected by moving discontinuities in a flowing liquid. Ultrasonic sound is transmitted into a pipe with flowing liquids, and the discontinuities reflect the ultrasonic wave with a slightly different frequency that is directly proportional to the rate of flow of the liquid (Figure 1). Current technology requires that the liquid contain at least 100 parts per million (PPM) of 100 micron or larger suspended particles or bubbles.

How to choose the right ultrasonic flow meter?

The key questions which need to be answered before selecting an ultrasonic flow meter or doppler flow meter are:

- Does the liquid have particulates of 100 ppm of 100 microns in size?

- Do you require a handheld or continuous process monitor?

- Do you require an analog output?

- What is the minimum and maximum flow rate for the flow meter?

- What is the minimum and maximum process temperature?

- What is the minimum and maximum process pressure?

- What is the size of the pipe?

- Is the pipe always full?

Design Variations

Clamp-on ultrasonic flow meters come in either single or dual-sensor versions. In the single-sensor version, the transmit and receive crystals are potted into the same sensor body, which is clamped onto a single point of the pipe surface. A coupling compound is used ultrasonically connect the sensor to the pipe. In the dual sensor version, the transmit crystal is in one sensor body, while the receive crystal is in another. Clamp-on Doppler flow meters are subject to interference from the pipe wall itself, as well as from any air space between the sensor and the wall. If the pipe wall is made of stainless steel, it might conduct the transmit signal far enough so that the returning echo will be shifted enough to interfere with the reading. There are also built-in acoustic discontinuities in copper, concrete-lined, plastic-lined, and fiberglass-reinforced pipes. These are significant enough to either completely scatter the transmitted signal or attenuate the return signal. This dramatically decreases flow meter accuracy (to within only ±20%), and, in most cases, clamp-on meters will not work at all if the pipe is lined.

Choose the right ultrasonic flow meter for your application

Ultrasonic Flow Meter with Totalization

Ultrasonic Flow Meter with Totalization

These ultrasonic flow meters are for applications with 100 PPM of 100 microns in size particulates or bubbles in the liquid. They are good for pipe sizes 0.25 to 120". These flow meters are used for flow measurement applicatons of 0.1 to 30 FPS. The FD-400 series has an optional display, and 4 to 20 mA output, Relays and 12 V pulse output options.

The FD-400 Series ultrasonic flow meter transmitter systems are designed for use where a sensor cannot be installed in the process. For liquids with suspended solids or aeration, standard and enhanced models. Available in non-invasive fixed position style. The FD-400 is an ideal doppler flow measurement solution. They are well suited for full pipes of liquid that contain at least 100 ppm of 100 micron or larger suspended particles or gas bubbles which act as sound "reflectors" and are necessary for operation. Ideal uses for this technology include: flow measurement of wastewater sewage, reactivated sludge, waste activated sludge, primary sludge, slurries, crude oils, lime slurries, phosphates and pulp stock.

Portable Ultrasonic Flow Meter

Portable Ultrasonic Flow Meter

The FD610 Series ultrasonic flow meter features advanced Trans-Phase measuring technology, providing accurate and reliable flow velocity assessments in closed piping systems. The FD610 Series utilizes a non-invasive clamp-on transducer which is placed on the outside of a pipe. Within seconds, the large 18 mm (0.7") LCD provides stable flowrate readings in feet per second or meters per second. This product operates on metal or plastic pipes containing liquids with more than 100 ppm of 100 micron or larger suspended solids or entrained gases.

Hybrid Ultrasonic Flowmeter

Hybrid Ultrasonic Flowmeter

Doppler technology is used to measure the flow rate of liquids with particulate and/or bubbles suspended in it. Transit time technology is used for clean liquids OMEGA’s FDH-1 Series hybrid ultrasonic flowmeter allows customers to select between doppler and transit time technology with a single instrument. Isolated analog output, frequency output and the ability to data-log to standard SD cards are standard included features. The FDH-1 is programmed via a menu driven QVGA LCD display with a 5 button interface panel.

Shop for Ultrasonic Flow Meters in Taiwan

The OMEGA Engineering Singapore office services all of Southeast Asia and Taiwan. We have Application Engineers and Sale Support Staff ready to assist

you with your technical questions, quotations and orders. A one-stop source for process measurement and control based in the heart of Singapore.

We provide support through web chat, e-mail and telephone. Come visit our office; view our

contact page for location details.

Ultrasonic Flow Meter | Related Products

↓ View this page in another language or region ↓

Ultrasonic Flow Meter with Totalization

Ultrasonic Flow Meter with Totalization

Portable Ultrasonic Flow Meter

Portable Ultrasonic Flow Meter

Hybrid Ultrasonic Flowmeter

Hybrid Ultrasonic Flowmeter

Medidores Ultrasonicos de Vazão

Medidores Ultrasonicos de Vazão

Débitmètres Ultrasoniques

Débitmètres Ultrasoniques

Caudalímetros Ultrasónicos

Caudalímetros Ultrasónicos

Caudalímetros Ultrasónicos

Caudalímetros Ultrasónicos

Ultrasonic Flow Meters

Ultrasonic Flow Meters

Ultralydsflowmålere

Ultralydsflowmålere

Débitmètre ultrason

Débitmètre ultrason

Ultraschall-Durchflussmesser

Ultraschall-Durchflussmesser

Misuratore di portata ad ultrasuoni

Misuratore di portata ad ultrasuoni

Ultrasonic Flow Meters

Ultrasonic Flow Meters

Caudalímetro ultrasónico

Caudalímetro ultrasónico

Ultrasonic Flow Meters

Ultrasonic Flow Meters

Ultrasonic Flowmeters

Ultrasonic Flowmeters

超声波流量计

超声波流量计

Ultrasonic Flowmeters

Ultrasonic Flowmeters

超音波流量計

超音波流量計

초음파유량계

초음파유량계

Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic Flowmeters